Guangzhou Haofeng Supply Chain Management Co., Ltd

Guangzhou Haofeng Supply Chain Management Co., Ltd is located in Guangzhou City, and our factory is also in Guangdong

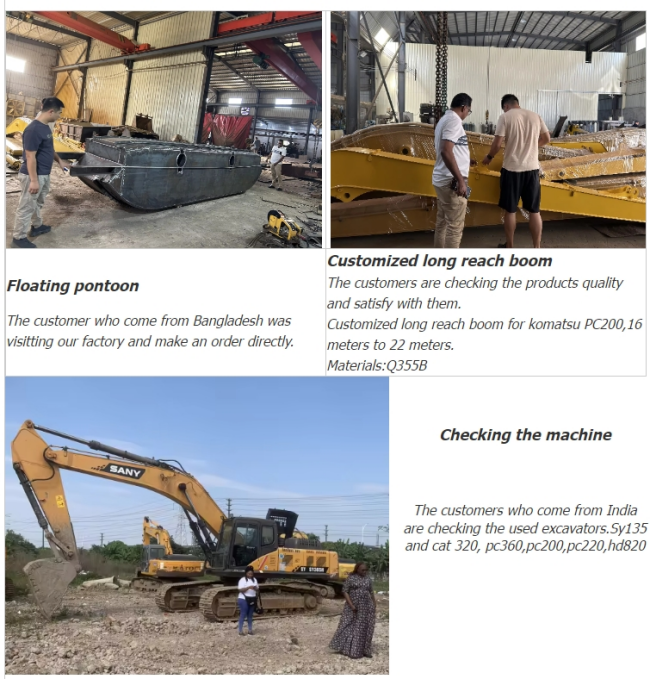

Province. We are a construction machinery manufacturer specializing

in customizing excavator extension arms, standard arms, amphibious

pontoons and buckets. Our company's products are suitable for

well-known brands such as Caterpillar, Hitachi, Hyundai, Kobelco,

and Komatsu.

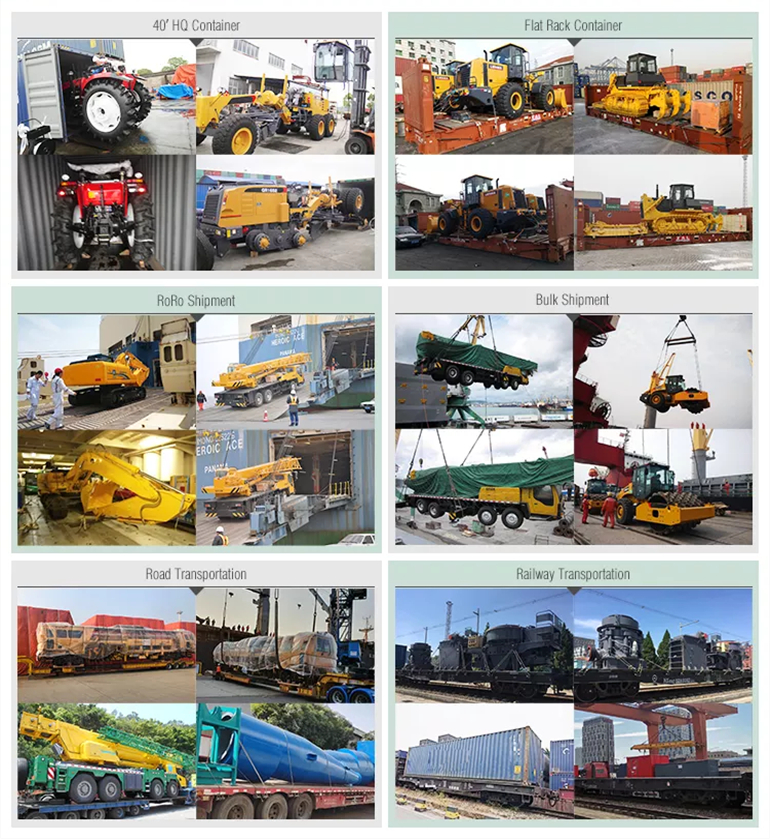

We have a large independent factory, a strong service

team and technical support, 100 employees, 15 sets of equipment,

and 4 production lines. With a material storage center of more than

3,000 square meters, factory customization can be quickly arranged

within 24 hours of placing an order. With the advantages of

manufacturing factories and global logistics supply chains, we can

produce quickly, book logistics containers, and deliver goods

quickly to achieve global sales.